0V missing at the brush head motor

The brush head has stopped working. I have cleaned all the removable parts properly and put it back together. However it still fails to spin. The vacuum motor is working fine!

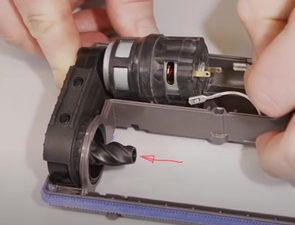

So, next I took the main body to pieces to reveal the PCB. Using my multimeter I found there was 21V across the vacuum motor terminals. But when I went across the brush head supply terminals I get nothing. However if I go on the positive terminal of the brush head and the negative of the vacuum motor I get 21V.

i’m aware that there is some sort of overload to protect the brush head motor in the case of drawing high currents, and im assuming it’s in the negative line, but where is it? And can I reset or replace?

Cette question est-elle utile ?

2

2  2

2

38

38

6 commentaires

Did you find a way to fix it or to only replace the motor part in the brushhead ?

par jsn

I have the same problem.

I have zero volts on the brush head supply terminals and have cleaned and tensioner the connectors but still no power.

When the brush head is connected and I pull the trigger the vacuum starts then stops then starts again and continues with suction but the brush hasn't moved.

When I pull the trigger without the brush connected the vacuum starts with no stop and start again. Could this indicate a sensor stopping the power for some reason?

par david

After assuming the power to the brush wasn't being given for some reason I manually rotated the brush and found it a little stiff even though there was no hair or the like tangled in it. I tried the power again and noticed it moved slightly then stopping again. I repeated a few times and it has started to work again.

I am now of the opinion that the power isn't supplied if the brush head motor is too stiff due to a fault or tangle, so after cleaning all electrical connections try loosening the resistance of the brush motor by giving it a few turns.

I have just put a tiny drop of wd40 to the brush drive bearing and it's working great. Fingers crossed, if it happens again I will be thinking it's the brush head rather than the supply which is disconnected at source to protect the vacuum.

par david

Did you get this fixed?

par georgiapch50

I have something similar - the vacuum motor works fine, the power to the brushes (I have tried both the large & small AND stripped and cleaned both of hair etc) - ranges from 3-4V which IMO isn't enough to turn the small motors on the brush heads. I have checked continuity back to the 20V battery and it is still 3-4V so I'm wondering if the battery is at fault or both brush motors have developed the same problem independently - what I don't understand is why the vacuum motor runs OK, but the power supply through the extension tubes only gives 3-4 V

par quixleyjl

Afficher 1 commentaire en plus